Value Engineering in Construction: The Comprehensive Guide

With this guide to Value Engineering, you can build smarter, cut costs without sacrificing quality, and discover how to maximize project value at every stage of construction.

Edward Gonzalez

Founder

Introduction

From skyrocketing material prices to shorter preconstruction timelines to tighter environmental regulations, the cost and complexity of construction projects have never been higher. Value Engineering, occasionally trimmed to the acronym VE, often comes up as a savvy estimating tactic. Yet VE commonly gets a bad rap as nothing more than cutting corners to save some cash.

According to statistics released by Associated Builders & Contractors, building material costs have risen by 37.7% since 2020. For general contractors grappling with holding onto their already razor thin profit margins, some level of formal VE is wise. For expanding profit margins, VE grows into a necessity.

The following guide aims to show estimating and budgeting teams at general contractors how strategic cost optimization can actually enhance quality and functionality rather than diminish it. We’ll also hit the fundamental principles, step-by-step methodologies, and common misconceptions surrounding Value Engineering. Let’s get into it.

The importance of Value Engineering in construction

Today’s construction industry faces multiple challenges—rising material costs, increasing sustainability requirements, and tight project timelines among them. Value Engineering addresses these hurdles by identifying the essential functions of a project and finding innovative ways to achieve them at a lower cost or with improved quality.

Whether you’re building a commercial complex, a residential development, or a large-scale infrastructure project, VE can help ensure you’re maximizing both your budget and your project’s long-term value.

History of Value Engineering

At its core, Value Engineering is a systematic method used to analyze a construction project’s functions and resources to achieve the highest value at the lowest life-cycle cost.

Rather than slashing budgets, for lack of a better term, all willy-nilly, VE focuses on identifying essential functions—those that contribute most significantly to performance, longevity, or user satisfaction—and finding ways to deliver these functions more efficiently. The goal is to maximize the ratio of function to cost.

“Function” is a bit of a loaded term that goes beyond just “does this thing work to the level of quality of the higher cost option?” It can take into account the more intangible preferences of an owner, like taste in aesthetics, for example.

The origin story of VE

Believe it or not, Value Engineering was originally born out of scarcity rather than a capitalistic drive to raise profit margins. Wartime in the 1940s provoked material shortages that put massive amounts of pressure on the manufacturing sector.

General Electric’s Lawrence Miles, may not have come up with the strategy to replace scarce materials with more widespread and affordable ones without sacrificing function—but he certainly receives historical credit as the first person to popularize it.

By implementing value analysis—now more popularly known as Value Engineering—companies were able to continue the high demand for production at a fraction of the cost, without needing to worry about material scarcity.

Ever since World War II, Miles’ savvy methodology became recognized as a standalone process that creeped into every sector including, you guessed it, construction.

Progression into construction

By the 1970s, large-scale construction projects that were on the more complex side were embracing Value Engineering as a means to work around budget constraints and material scarcity. From government infrastructure programs to private commercial projects, VE steadily gained acceptance over the years for its ability to save GCs money without sacrificing quality for the owner.

Nowadays, Value Engineering is universally recognized as a staple of preconstruction to ensure maximum impact. All GCs have some degree of VE formality, with the largest and oldest GCs typically having a much more systematic approach than the upstarts which are still at the point where they’re finding what works and what doesn’t.

The 4 key principles of Value Engineering

1. Function over cost

Value Engineering focuses on strategically minimizing costs without compromising essential functionality. If function is diminished, the cost cuts simply aren’t worth making.

2. Systematic approach

Value Engineering isn’t a one-off decision about cutting corners but a structured methodology with clear phases including (but not limited to) Information, Speculation, Evaluation, Development, and Presentation. Buildr is an excellent choice for an AI preconstruction platform that provides a systematic framework to facilitate VE collaboration.

3. Collaboration

The full scope of Value Engineering touches on design, engineering, budgeting, and project management, which means it inherently benefits from a broad range of perspectives. When all the necessary stakeholders successfully collaborate, you can be certain that the final Value Engineering solutions are thoroughly vetted. Siloing is what constricts the full potential of VE.

4. Psychological safety

Psychological safety is an important aspect of a workplace that encourages free thinking and creativity. By fostering an environment where all team members can freely throw out ideas—no matter how unconventional—they increase the odds of discovering innovative solutions.

For a more in-depth walkthrough of each of these four principles, be sure to check out our blog.

Core benefits of Value Engineering

Value Engineering offers a powerful way to lower both upfront and long-term expenses by analyzing project components—such as materials, labor, and maintenance—to pinpoint optimal cost savings. Perhaps the exact opposite intent of the cheapness in the phrase “cutting corners,” VE can actually enhance quality and performance by identifying design improvements that strengthen structural integrity and elevate occupant comfort, all within budgetary constraints.

When introduced early in the design phase, VE also streamlines project efficiency by detecting potential bottlenecks before construction begins, reducing mid-project changes and delays. At the same time, optimizing material usage and integrating energy-efficient systems can lessen a project’s environmental impact and operational costs—often aligning with certifications like LEED while meeting stringent sustainability goals.

Lastly, VE helps teams mitigate risks by spotting design flaws, material weaknesses, or budgetary gaps well ahead of time. By addressing these issues proactively, stakeholders can conserve resources, maintain safety standards, and ensure on-time completion, paving the way for a smoother construction lifecycle from start to finish.

Common misconceptions about Value Engineering

Myth: Value Engineering = Cheapening the Project

As alluded to, one of the most prevalent misinterpretations of Value Engineering is that it’s akin to cutting corners. In reality, VE emphasizes maximizing the function-to-cost ratio. By thoroughly evaluating different materials, methods, or designs, it aims to preserve—if not enhance—quality and performance.

Myth: VE occurs at the tailend of a project

Some GCs wait until late in the construction process to initiate Value Engineering, treating it like a last-minute cost-saving exercise. However, VE is most impactful when introduced in the early design or planning stages of preconstruction—allowing potential inefficiencies or oversights to be addressed before they become costly issues. This is why Buildr’s preconstruction platform makes such an effort to foster VE.

Myth: Only large projects benefit from VE

While more complex projects can certainly see substantial benefits, small and medium projects also benefit from a structured VE approach. Even minor tweaks—like switching to a more durable material or refining a design layout—can lead to notable budget savings and quality improvements that allow a smaller GC to boost their reputation with their clients and take on more (and better) volume. VE’s principles are universal and scale to projects of all sizes.

Myth: VE takes too much effort and time

A well-executed VE process does require tight-knit collaboration and thorough analysis which takes time and effort. But it often saves so much more time later by preventing rework, design errors, and mid-project revisions. By proactively addressing issues, teams spend less time fixing problems down the line. This equates to a smoother, more efficient construction timeline overall.

Step-by-step approach

1. Information gathering

Value Engineering always starts with a meticulous collection of all relevant project data, including goals, constraints, design parameters, and client expectations. This foundational step establishes a clear understanding of the project scope—what the building or infrastructure must achieve, the budgetary limitations, and the schedule requirements.

During this phase, it’s crucial to engage all key stakeholders (owners, owners’ reps, architects, engineers, trade partners, sometimes local municipalities) to ensure that every functional need is correctly identified and captured.

2. Functional analysis

Once all basic info is attained, it’s time for the team to break the project down into its primary and tertiary functions. This process, while a little different for every GC, focuses on identifying what each component or system is supposed to do.

Tools like the Function Analysis System Technique (FAST) diagram can visually map out relationships between functions, helping the team see where potential overlaps or redundancies exist. By clarifying these functions, project teams can better determine which elements are truly essential to project performance and user satisfaction.

3. Brainstorming & idea generation

With project functions defined, the next step is an open-ended brainstorming session. Here, the emphasis is on generating as many ideas as possible, without initial concern for feasibility or cost. This encourages out-of-the-box thinking that might uncover innovative solutions. To get the best results, it’s recommended to create a collaborative and psychologically safe environment where all participants feel comfortable proposing new concepts.

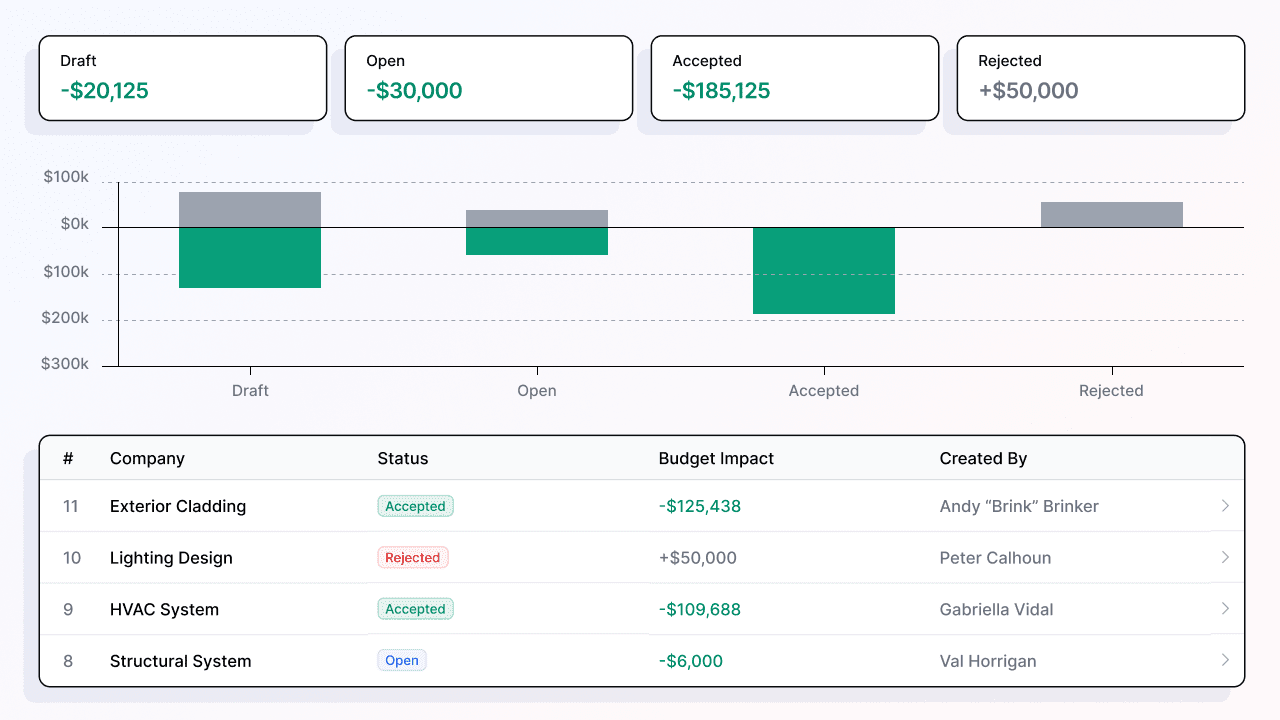

Buildr’s VE framework includes budgeting tools which allow for suggestions that require evaluation and approval before making it into the final budget.

4. Evaluation & feasibility

After compiling a wide range of ideas, the group narrows down the options through a structured evaluation. Each idea is vetted based on criteria such as cost-effectiveness, technical feasibility, impact on performance, and alignment with the project’s overall objectives. Some teams use scoring methods—for example, assigning numerical values for cost savings, ease of implementation, and sustainability—to compare proposals in an objective way. By the end of the evaluation phase, the team is left with a shortlist of promising solutions in their lap, ready for further development.

5. Proposal development

In this phase, the ideas that floated to the top from the evaluation/feasibility phase are refined into formal proposals. This includes drafting cost-benefit analyses, technical specifications, and any necessary design modifications. The more detailed these proposals are, the easier it is for stakeholders to understand exactly what is being changed, why it’s beneficial, and how it will affect the project’s timeline and budget.

6. Presentation and implementation

Once the proposals are fully fleshed out, they are presented to the client and/or other decision-makers. This is where a good sales acumen can come in handy; a pitch that speaks to the emotions of the owner is everything. If all goes well, approvals are obtained, and the team integrates the decided-upon recommendations into the existing project plan.

7. Post-implementation review

The Value Engineering process doesn’t end once changes are put into action. After the new solutions have been integrated, the team conducts a thorough review to assess their effectiveness. Did the changes deliver the anticipated cost savings? How did they affect the project’s schedule or overall quality? By documenting these outcomes, the team gathers valuable lessons that can be applied to future projects. This final step completes the VE cycle and encourages continuous improvement over time.

As a comprehensive preconstruction solution, Buildr’s estimating software is equipped to capture every Value Engineering option and track all greenlit decisions, leveraging your historical data to foster better outcomes.

How Buildr helps GCs execute Value Engineering

Tracking value engineering ideas in spreadsheets and email threads can lead to miscommunication, missed opportunities, and a lack of visibility. That’s why Buildr created a purpose-built Value Engineering tool to help general contractors streamline this process.

Now you can log cost-saving ideas, collaborate across departments and with clients, and compare the budget impact of multiple VE options—all in one place. Once a change is accepted, it’s automatically integrated into your live budget, so nothing slips through the cracks.

It’s a simpler, more transparent way to reach your target budget without compromising on scope or quality.** **As a powerful storytelling tool, it transforms your project history into a visual narrative, making every decision easy to follow and ensuring all parties stay aligned and informed.

To see Buildr’s VE in action, hit the “Schedule Demo” button in the top right of this page to get connected with a product expert. If you’re already a customer, be sure to reach out to your customer success manager and they’ll be more than happy to show you the ropes!

Conclusion

At the end of the day, Value Engineering in construction is more than just costcutting; it’s a holistic approach that marries function and cost at every stage. By systematically identifying innovative solutions that cut costs without compromising quality, VE lays the groundwork for continuous improvement and positions your projects to adapt to emerging trends—such as AI-driven cost modeling and advanced sustainability requirements.

Now that you understand how a preconstruction process infused with a sound VE methodology can streamline operations and boost overall project performance, it’s time to put these principles into practice.

To learn more about how an AI preconstruction workspace like Buildr can provide you with a better framework for Value Engineering to set your business up for success, be sure to schedule a demo with a product expert here: Schedule a Demo